Best of British: The art of luxury bed manufacturing and spring engineering from Harrison Spinks

For over 185 years, Harrison Spinks has been at the forefront of luxury bedmaking, combining traditional craftsmanship with pioneering innovation. As a proud British manufacturer, the company is committed to responsible production, ensuring every mattress is handcrafted using natural, responsibly-sourced materials, and is made glue-free, foam-free and free from potentially harmful chemical treatments.

From its homegrown hemp and flax to its unique glue-free pocket spring system, over 95%* of the components in a Harrison Spinks mattress are manufactured in-house, providing exceptional comfort while having full control over the whole manufacturing process.

A commitment to British Wool

One of the key pillars of Harrison Spinks’ responsible bedmaking ethos is its commitment to using British Wool. As the first bedmaker to partner with British Wool on its Traceable Wool Scheme, Harrison Spinks sources the finest wool from British farms, supporting local farmers who receive a premium price for their product. The wool used within the luxury mattresses includes rare breeds such as Herdwick sheep, prized for its resilience and springiness. Harrison Spinks also raises its own sheep on its 300-acre farm in Yorkshire, reinforcing its dedication to homegrown, high-quality materials.

Harrison Spinks Sheep

Precision weaving naturally fire-resistant fabrics

Wool is an exceptional material for mattress fillings, being naturally hypoallergenic, antibacterial, and moisture-wicking; it helps regulate temperature for a restful night’s sleep throughout the year. It is also inherently fire-resistant, and by weaving its own wool-rich ticking fabric in-house, Harrison Spinks eliminates the need for fire retardant chemicals across its mattress production.

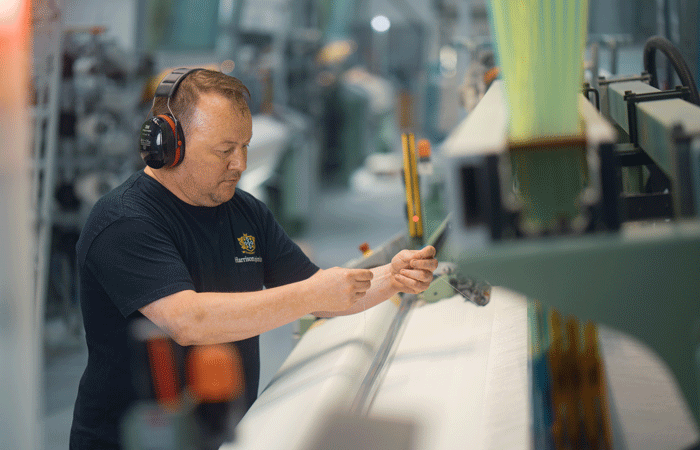

Weaving mattress ticking fabric on state of the art weaving looms

State-of-the-art weaving looms in Yorkshire allow Harrison Spinks to create mattress covers that are soft, breathable and luxurious, while ensuring every mattress remains as natural as possible.

Homegrown hemp and flax from the Harrison Spinks farm

Harrison Spinks stands apart as the only British bedmaker to grow its own mattress fillings. Hemp and flax, cultivated on its Yorkshire farm, are integral to its ethical production process. Hemp is not only strong and durable but also naturally temperature-regulating and antibacterial, while flax is a more responsible alternative to cotton, thriving in the British climate and requiring only rainfall and no additional water to grow.

Homegrown hemp from the Harrison Spinks farm

By growing its own filling fibres, Harrison Spinks significantly reduces its environmental footprint while maintaining complete control over quality. Beyond its own farm, the company also collaborates with a cooperative of local farms to grow the hemp needed for the mattress production.

The company is committed to environmental conservation and supports initiatives such as the Wild Ingleborough project, which aims to restore Yorkshire’s natural habitat, protect endangered plant species, and promote eco-conscious farming.

Pioneering spring technology for long-lasting comfort

As pioneers of the world’s first glue-free, 100% recyclable pocket spring system, Harrison Spinks has set a new standard in mattress design and comfort. Its pocket springs – including the award-winning revolutionary Cortec™ Quad spring system and high-density, ultra-responsive micro springs – are sonically welded rather than glued, ensuring full recyclability at the end of their lifespan. This also allows the springs to move independently and contour to the body for cloud-like comfort.

Micro springs manufactured in Leeds

All springs are designed and manufactured in-house at the company’s Leeds-based facility, using machines developed by expert engineers in its own spring development department. Ultra-fine wire for these springs is produced to precise specifications on Harrison Spinks’ own dedicated line at a wire-drawing facility in Scunthorpe. The carefully engineered springs provide targeted lumbar support, adapting seamlessly to the body’s movements and delivering unrivalled support and targeted relief of pressure points without the need for foam.

Harrison Spinks wire drawing

Mastering traditional handcrafted techniques

Luxury is in the detail, and at Harrison Spinks, expert craftsmanship is at the heart of every mattress. Skilled artisans train for months to perfect techniques such as hand side-stitching, tufting, and tape edging, ensuring each mattress is exceptionally comfortable and stands the test of time. The meticulous hand side-stitching process alone can take more than eight hours per mattress, reinforcing edge support and enhancing stability and durability across the entire sleep surface. Hand tufting secures layers of fillings in place with an extremely large needle and thread, preventing shifting over time and maintaining superior comfort.

As a family-run business spanning five generations, Harrison Spinks upholds a tradition of excellence while constantly innovating. Every mattress is assembled by hand in the company’s Yorkshire factory, where each layer of natural fillings and supportive spring systems are carefully positioned to create a sleep surface tailored to perfection.

Handmade headboards and divans, upholstered in hemp

Harrison Spinks extends its carefully curated and ethical approach to its range of handmade headboards and divans. Crafted using FSC-certified wood, sourced from responsibly managed forests that meet rigorous environmental, social, and economic standards, the brand ensures that its beds are as eco-friendly as they are luxurious.

Headboards being upholstered at the Leeds factory

The business weaves upholstery fabric using its own homegrown hemp and responsibly sourced British wool, which is the final finishing touch on the handmade headboards and divans and is also naturally fire-retardant and free from chemical treatments.

A legacy of innovation and responsible manufacturing

Harrison Spinks represents the pinnacle of British bedmaking, seamlessly blending heritage craftsmanship with cutting-edge innovation. From its homegrown hemp and use of traceable British wool to its revolutionary glue-free springs, the company is redefining what it means to create a luxury mattress.

As a result of these industry leading initiatives, Harrison Spinks is a proud holder of three King’s Awards – for Innovation, International Trade, and Sustainable Development – and has been honoured with a total of eight King’s and Queen’s Awards for Enterprise, recognising its outstanding contributions to the furniture industry. The business was also awarded Bed Manufacturer of the Year 2024/2025 at the National Bed Federation Awards, further cementing its reputation for excellence.

More than just a bedmaker, Harrison Spinks is a champion of responsible British manufacturing, dedicated to crafting beds that offer unparalleled comfort while protecting the planet for future generations.

*By weight

Find Harrison Spinks on Supplier Finder

Supplier Finder is the UK’s only search platform for accredited suppliers of commercial interior furnishings.

At Supplier Finder, our mission is simple: to help you find the perfect commercial furnishing suppliers for your interior schemes and projects. We understand the importance of having confidence in the suppliers you specify and the products that bring your designs to life. That’s why each supplier featured on our platform is accredited through Commercial Interiors UK’s rigorous membership application process. This ensures that you engage with only the best in the industry!