Flooring Innovation

Ahead of our BCFA Open event on the 26th & 27th October 2016 at Manchester Bridgewater Hall, we discuss innovation with BCFA members exhibiting at the event, Newhey and Johnson Tiles.

Design Excellence Driven by Innovation in Sustainability

BCFA Open exhibitor Newhey, a leading British manufacturer of contract carpets for the hotel, leisure and entertainment sector, focus on their sustainability objectives and have seen how this innovation has positively informed their new product launches.

In 2009, Newhey collaborated with their backing manufacturer to develop a revolutionary solvent free hot melt adhesive backing system, ‘Evobac’. Evobac is produced from 100% recycled plastic bottles and is applied by Newhey on their 4 metre wide hot melt secondary backing line, the first in the world.

Sustainability has been addressed across the Newhey manufacturing facilities, resulting in a reduction in carbon footprint by 118 tonnes of CO2 with a further 210 tonne reduction in the pipeline, reduction in waste to landfill by 50% and reduction in transport costs by 50%. The entire Newhey production process happens within a small geographical radius with wools scoured in Bradford and Cumbria, spun in Huddersfield and tufted in Newhey on the outskirts of Manchester.

Newhey’s innovation in sustainability within their business has moved hand in hand with exciting new design briefs for the Newhey design team. The Newhey design team have access to new materials and processes, they are also presented with material and process limitations which create briefs which push the designer’s creativity and lead to innovative design solutions. A clear example of this is the Natural Wool Collection, launched by Newhey in 2015, which is entirely dye and chemical free and celebrates the natural tones within the Cumbrian mountain wool. This collection is celebrated by Newhey’s customers for not only its sustainable credentials but also for its natural beauty and design excellence.

Register now to visit Newhey on Stand 9A on Wednesday 26th and Thursday 27th October 2016 at BCFAOpen, a contract furniture and furnishings exhibition at the iconic Bridgewater Hall in central Manchester. For news on BCFAOpen you can follow our updates on Twitter, Instagram, LinkedIn and Google+

Fusing Traditional Techniques with Innovation

BCFA Open exhibitor and leading UK manufacturer Johnson Tiles has over 100 years’ experience, fundamentally what they did 100 years ago is the same as what they do now – they make great tiles, the difference lies in how the tiles are made. Fusing traditional techniques with innovative technology has enabled Johnson Tiles to remain at the forefront of the manufacturing industry.

Renowned for working on large-scale projects in a variety of sectors, Johnson Tiles is no stranger to embracing innovative technologies, their expert Artile technology, replicates even the most intricate high resolution designs to be fully translated on to glazed tile without any loss of quality. Artile has enabled projects such as Clare Twomey’s unique installation – Time Present and Time Past – at the William Morris Gallery, to come to fruition.

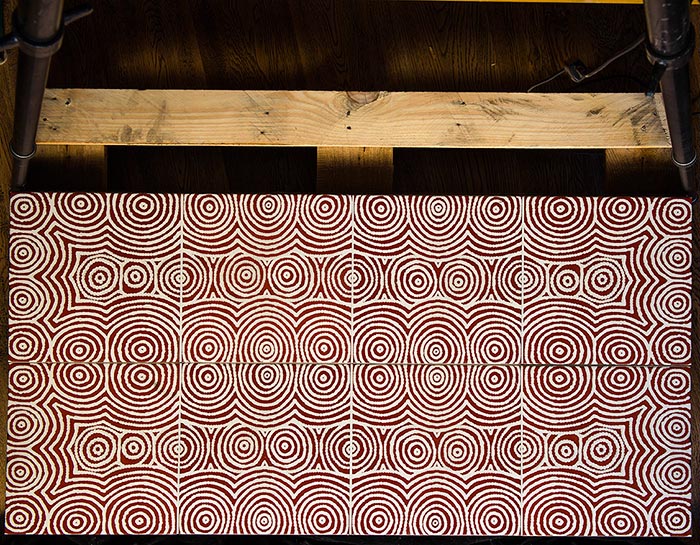

Another recent project saw Johnson Tiles reproduce Aboriginal artwork on to ceramic tile, something that required a high level of skill.

Through continued innovation, Johnson Tiles not only follows, but also dictates interior trends. Slim format tiles made of the thinnest porcelain; 3D textures; tiles which look and feel like natural stone or wood and micro patterns – are all products that demonstrate the company’s skills, and dedication to new technology.