Interview: Fashion Designer Savvas Alexander

When we heard about Royal College of Art Fashion Design Graduate Savvas Alexander, and the concepts his work explores, we knew we needed to see what the commercial sector could learn from this innovative and boundary pushing designer.

Read our conversation with Savvas and hear about the ways in which this exciting designer has worked with sustainable materials and processes, waste free design, inclusivity and where he has found cross-sector inspiration.

We started by asked Savvas to tell us about himself and his background.

My name is Savvas Alexander. I’m a designer and maker from Yorkshire, though I now work in London. I studied my BA in Fashion at the London College of Fashion and subsequently got a scholarship to study MA Fashion at the Royal College of Art. From graduating, I started my company and have since been part of the Atelier100 2022 cohort, which is an initiative launched last year between Ingka Group (IKEA Retail) and H&M to fund and support emerging, local talent within design. I was also a finalist of the Fashion District’s Design Futures competition.

We hear you’ve launched a new fashion collection, with all garments made-to-order. What’s the thinking behind this?

That’s correct. I’ve just launched my e-store on my website with a capsule collection of 11 items. The majority are made-to-order using super-fast techniques I have been developing over recent years, which allow customers to receive their orders in good time. This idea is all about countering the mass production of stock and waste we see in the industry. I really believe made-to-order is the future for how this industry should work.

As a young business owner, it also goes some way to help me operate financially, meaning I don’t have to put up vast amounts of money for producing items that might not sell through. Instead, I either hold some fabric in my studio or order it in when a sale comes through.

Tell us about other sustainable initiatives you’ve included. We’re especially interested in the ‘no hems, no zips’ aspect of your designs?

Part of my philosophy is about reducing what isn’t necessarily required. This helps with faster production times for made-to-order fulfilment, alongside the end of life consideration should the garment reach the stage where it needs to be taken apart and recycled for example. It means that the speed of disassembly would be very fast.

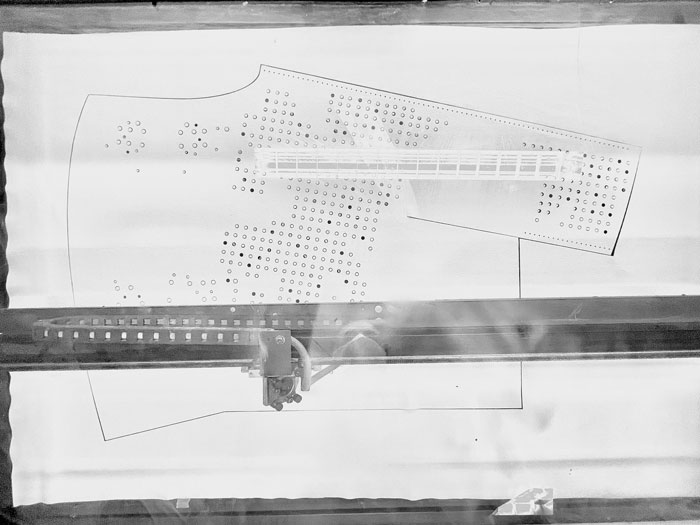

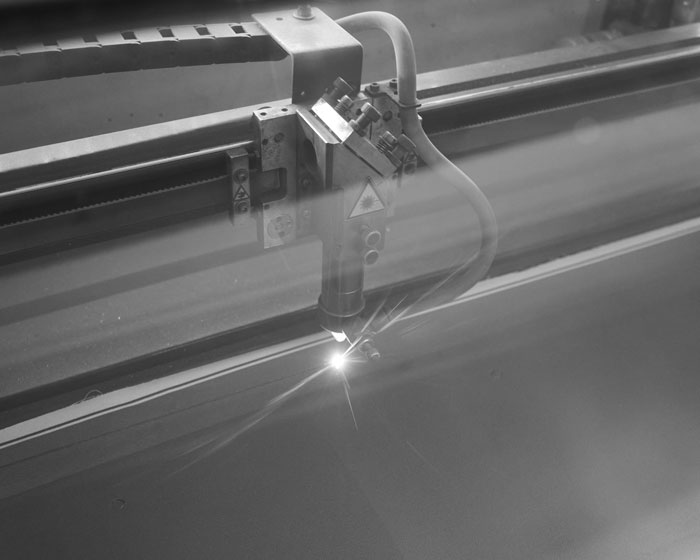

I do this through working mostly with laser-cutting technology to produce the garments as this seals the edges, meaning we don’t need extra sewing on the hems. This also enables my circular closure system where the fastenings are screwed into laser-cut holes, reducing the need for extra trimmings and sewing that is both time consuming and potentially wasteful. Again, this also helps with end of life and current garment repair. Should a fastening break, for example, it is much easier to replace than a whole zip would be.

Given my design output comes from digital files, I am also able to offer rapid adjustments for more bespoke pieces too.

Some, but not all, of your clothes and bags feature recycled and reclaimed materials. How difficult was it to find the textiles you wanted in the marketplace?

The drawback to my system is that I have to use predominantly synthetic fibres because they provide a clean seal on the edge that doesn’t fray, so I do try and offset this with recycled materials where possible, but of course they are still difficult to source in the low quantities I am currently operating with.

The main sourcing issue is really about reaching minimum order quantities, or trying to source locally which is part of my future vision. The UK has a really poor performance fabric infrastructure and so most of my materials come from Europe or Asia, meaning a whole host of added costs now due to Brexit unfortunately.

One of my materials for outerwear and accessories is from the Japanese company Toray, who were kind enough to sponsor me with their Ultrasuede fabric during my MA and I have continued using it, in particular their compositions that use plant based or recycled PET, which comes from a film scrap sourced from their film department factory.

I know it isn’t perfect but a lot of natural materials also contribute to high levels of waste or raw material usage, so I prefer to focus on trying to use less fabric, and building in disassembly for when material recycling improves and becomes more accessible.

What are the influences behind some of the stand-out details of your clothes, including the draping and laser-cutting?

My process really starts by draping on the mannequin and seeing what I can create using single pieces of cloth, forming and moulding them around the body and taking advantage of pleats and darts rather than adding in multiple panels and seams.

I follow a lot of Japanese ideas when it comes to design. Think kimono sleeves and pattern-cutting where entire garments are cut using really simple and low structures with meticulous attention to fine detail.

All of this feeds into the system of making the product really simple to construct. Everything gets laser-cut, which is really fast and precise, and the sewing time is usually quick because I have worked on reducing everything down to its most minimalist level.

I also laser-cut the circles for the closures which began as a practical product development idea, and now also filters into my visual language and aesthetic. I’ve started building a book for references for everything to do with the circle – from fine art to architecture and product design, I believe this will feed into future designs.

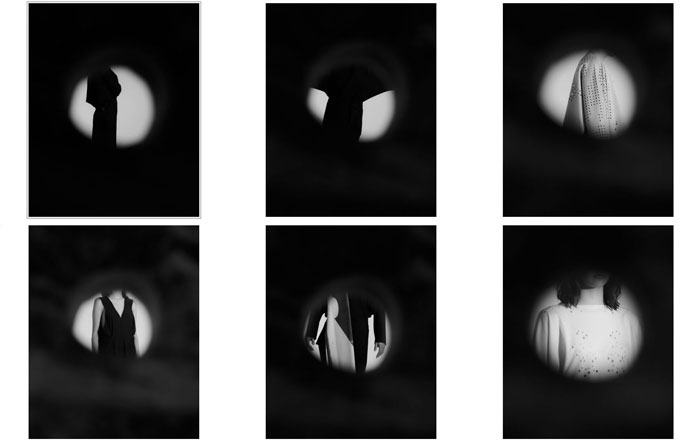

Your features both female and male models. Is gender inclusivity high on your agenda?

It is very high on the agenda. When I first started studying, I was on a menswear programme so that was my focus, but actually during lockdown I shifted to testing womenswear because I could do fittings on my partner and design clothes with her in mind. Now this has developed into mostly agender clothing, with some men’s and women’s specific pieces on each end of that scale.

This really feeds into the conscious creation aspect of my values as I don’t want clothing to be restrictive in the sense it can be only for a small group of people or scenarios, and potentially end up being wasted by the consumer. Shared wardrobes across couples, friends and family while still feeling great in the piece you are wearing is a super interesting idea to me.

To bring this into reality, I developed sizing techniques on trousers, skirts and jackets specifically so many different shapes and sizes can wear the piece, again through a variation on my circular closure system that allows for size adjustment.

What does the fashion industry need to do to improve its sustainability record and processes?

Firstly switch from a growth model to a sustain model as a whole and stop using ‘Sustainability’ as just a marketing tool, though that will probably never happen!

I think if we can become smarter in how we produce, and at reducing our consumption of clothing, then that will go a long way. Moving to more agile production methods, shifting to local materials and developing better infrastructure could all help reduce emissions and waste.

I also think there needs to be new legislation on combatting waste, poor quality and poor working conditions across many of the big fast-fashion brands as they are the ones creating the most damage.

What do you think other industries can learn from some of the directions you’ve taken?

To be honest a lot of my work has actually been influenced by other industries such as furniture and product design.

I think really focusing on design being intertwined with production and manufacturing is really key to understanding how we can problem solve within design. Embracing technology and experimentation within technology is very important, looking at how we can use new and existing machinery for our benefit. In general, let’s try and take more risks in our work!

Contact Savvas Alexander