Leading the Way in UK Manufacture: Abbotsford Textiles Sets the Standard for Contract Fabrics

Abbotsford Textiles is a trusted UK manufacturer and supplier of durable contract fabrics, woven and finished in the UK ensuring consistent quality. Designed for the demands of commercial and contract interiors, upholstery, and soft furnishings, their collections offer reliable solutions that balance both functionality and refined aesthetics.

The journey from fibre to fabric is a meticulous process, and at Abbotsford Textiles, they maintain the highest standards at every stage. With their in-house manufacturing expertise, they can adjust the process at any point, ensuring complete control and delivering exceptional quality you can trust.

Classic Melton

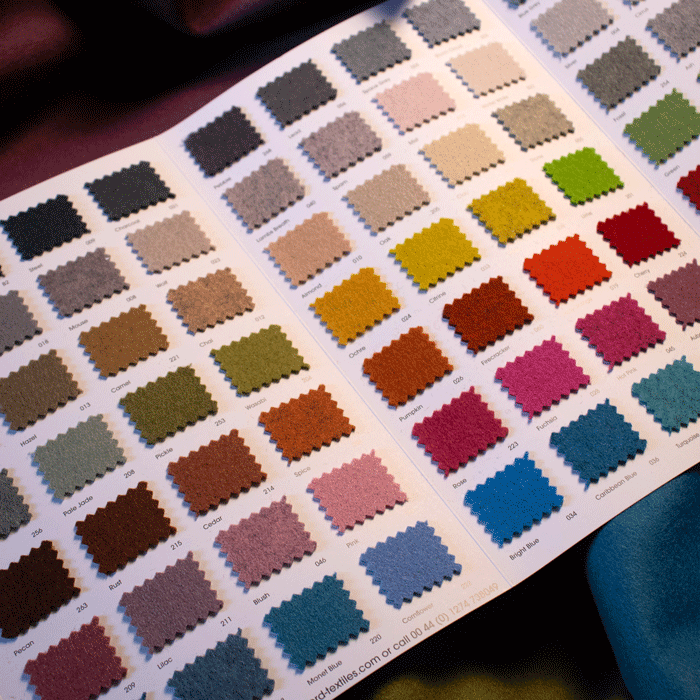

The Classic Melton collection, woven from 100% Pure New Wool, is a durable and versatile choice for high-traffic interiors. With its smooth, felted finish, it offers both resilience and a soft, tactile feel, making it ideal for upholstery, drapery, acoustic solutions, and soft furnishings. Available in 100 colours ranging from vibrant, rich shades to muted tonal hues, it provides flexibility across a wide range of projects, from commercial offices and hospitality venues to residential spaces. Its durability and refined aesthetic make it the preferred choice for those seeking both style and long-lasting performance.

Exhilarate/London

With a blend of 92% Pure New Wool and 8% Nylon, the Exhilarate/London collection features five striking woven stripe fabrics, each designed to introduce vibrancy and energy into any space. Whether used as a focal point or paired with the Classic Melton collection, these stripes enhance and complement surrounding colours. Perfect for both commercial and residential spaces, the Exhilarate/London fabrics provide dimension and contrast, creating a dynamic, welcoming atmosphere that elevates interior design projects.

Texture

The Texture collection is a boucle fabric, woven from a blend of 85% wool, 10% mohair, and 5% nylon. As a popular and contemporary choice in interior design, it combines sophistication with durability, making it ideal for commercial applications. Available in 19 colour options, including natural greens, subtle greys, rich jewel tones, and captivating blues, offers a versatile palette to complement any interior design scheme. This collection strikes the perfect balance of style and functionality, delivering exceptional quality and reliability for high-traffic environments.

Each fabric collection at Abbotsford Textiles represents the culmination of a precise and carefully managed process, ensuring exceptional quality at every step, from fibre sourcing to the final finish.

The Fibre-to-Fabric Journey

Raw Fibres: Sourcing Excellence

With over 210 years, their fibres division source the finest raw materials globally, building strong partnerships with trusted suppliers to ensure the finest quality, sustainably sourced and traceability throughout the process.

Blending: Creating the Perfect Blend

This process opens the fibre and blends different colours or types to create the desired composition for handle, wearability, and colour mix.

Carding and Combing: Preparing the Fibre for Spinning

Fibres are lubricated with oil and water, then processed through combing cards to separate, disentangle, and align them. Shorter fibres are removed, leaving the longer, stronger strands to form the ‘top.’ This crucial step produces untwisted slivers, ensuring the fabric’s strength and durability.

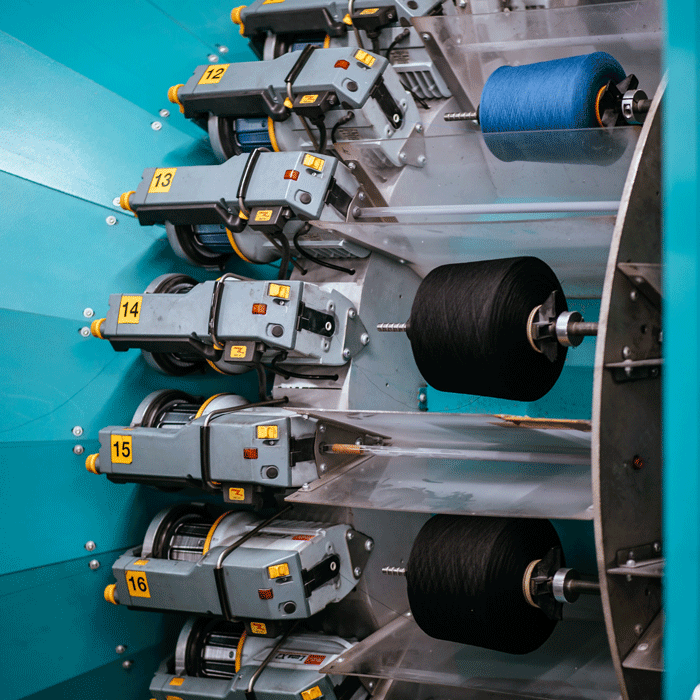

Spinning: Creating Seamless Yarn

The cleaned and carded fibres are rapidly twisted to create seamless, durable yarn, which can vary in thickness, texture, and properties based on the fibre type used and the end-product.

Dyeing: Perfecting the Colour

Yarn dyeing consists of dyeing the thread cone prior to being woven, giving a more three-dimensional colour.

Piece dyeing dyes the woven cloth, and provides a cleaner, more even colour across the fabric. Throughout the process, the colour of the cloth is checked against the quality sample, ensuring consistency of colour.

Warping: Preparing the Loom

A woven fabric consists of warp yarns running lengthwise and weft yarns crossing width wise.

Warping is the first stage, where yarns are wound onto a drum and then transferred to a weaver’s beam, ready for the loom.

Weaving: Bringing the Fabric to Life

On the looms, the warp and weft are interlaced to form fabric, with numerous weave types available. After weaving, each piece undergoes strict quality control.

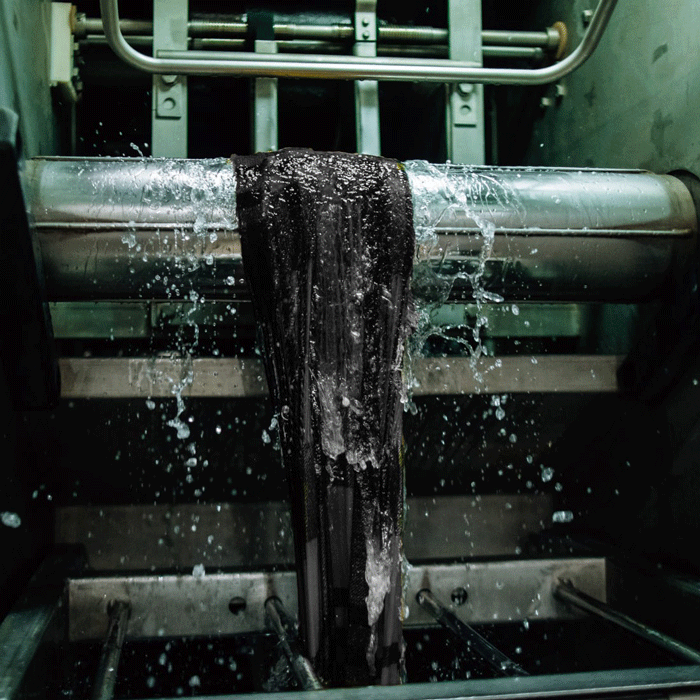

Finishing: The Final Touch

Finishing transforms raw fabric into its final form, where up to fifty different techniques, including washing, stabilising treatments, steaming, singeing, and pressing, are applied to achieve the desired hand feel and appearance. The fabric is washed using only their famously soft Pennine water, an essential element in the finishing process. Manufacturing in their UK mills allows them to adjust and monitor quality throughout production, ensuring consistently high standards.

Find Abbotsford Textiles on Supplier Finder

Supplier Finder is the UK’s only search platform for accredited suppliers of commercial interior furnishings.

At Supplier Finder, our mission is simple: to help you find the perfect commercial furnishing suppliers for your interior schemes and projects. We understand the importance of having confidence in the suppliers you specify and the products that bring your designs to life. That’s why each supplier featured on our platform is accredited through Commercial Interiors UK’s rigorous membership application process. This ensures that you engage with only the best in the industry!