Material Rescue! With Jim Biddulph

“We’ve started a new initiative, we’re calling it Material Rescue.” I’d already been enjoying catching up with Scott Campbell, founder of Surface Matter, at the Surface Design Show back in February, but this comment particularly piqued my interest. “You should come and check out what we’re up to with it at our new space in Rye.” I was sold; not only did I want to know more about this circular material scheme, but Rye is one of my favourite destinations along the south coast.

Fast forward to May and a plan was hatched to visit the warehouse in conjunction with a trip to another of the annual trade show roster, Clerkenwell Design Week. That way I could consolidate and minimise the impact of my travel, and better still, with the weather finally starting to pick up, I’d combine another passion and cycle from my home in Margate along the coast, before later getting on the train to London. Unfortunately, a virus amongst the Surface Matter team scuppered those plans. Still, undeterred, I head to CDW with my bike, and after a pretty soggy day in the city get on the train to Ashford International the following morning. Thankfully the sun decides to shine, and I weave my way south, down the flat country roads until the medieval citadel gracefully appears upon the horizon.

I’d always wondered what industries might take place in the harbourside factories nestled just beyond the town, and it turns out materials play a big part. In one plot there are tonne bags of aggregate as far as the eye could see, while along the road British Gypsum have been operating since the 1800s, each working around the ever-changing tide to bring their construction materials in. Next door, adorning the sizable B1 unit, I spot the trademark black and white livery of Surface Matter, a brand I had first encountered over a decade ago while working at Material Lab. Our paths have crossed at regular intervals ever since, not least at their London space located on the edge of London Fields, which before opening the Rye site had been their sole home since 2015. It too plays host to a studio filled with colourful and texturally rich materials, although there is an abundance of samples from six key suppliers, for whom Surface Matter is the sole UK distributor.

To fully appreciate what the team is all about and how they operate – particularly in terms of the Material Rescue initiative – it’s useful to understand the brand’s DNA; something that Scott and co-founder Jane have been developing since even before the inception of the company. Scott’s working life began in the world of material supply and distribution, overseeing sales and logistics for a large timber merchant for the best part of two decades. During this time he took on an additional new account with a material manufacturer from the USA called Richlite. Their sheet material of the same name is incredibly durable and versatile, but the subtly mottled surface also has a surprise up its sleeve – it’s made from paper. Multiple layers are saturated with a thermosetting resin, transforming them into a stable, nonporous, heat and water-resistant board that can be used both internally and externally. “I could see it was an amazing material. It’s been used in aerospace and marine contexts, and they’d already opened up new markets in the skate industry with Skatelite – the perfect material for cladding ramps – so I could see the potential for the A&D sector.”

When Scott parted ways with the timber merchant he patiently worked with each party to gain the exclusive UK distribution rights to all Richlite materials, which now also includes the richly textured Shaped range. The fact that these surfaces used recycled consumer waste or FSC-certified paper with no additional dyes was no coincidence either, and rather the perfect seed to sow at the being of the Surface Matter journey. The other materials to follow in the ongoing development of the team’s product portfolio are made from recycled content and seek to challenge our perception of waste by applying a new sense of value and purpose to post-industrial plastics and textiles.

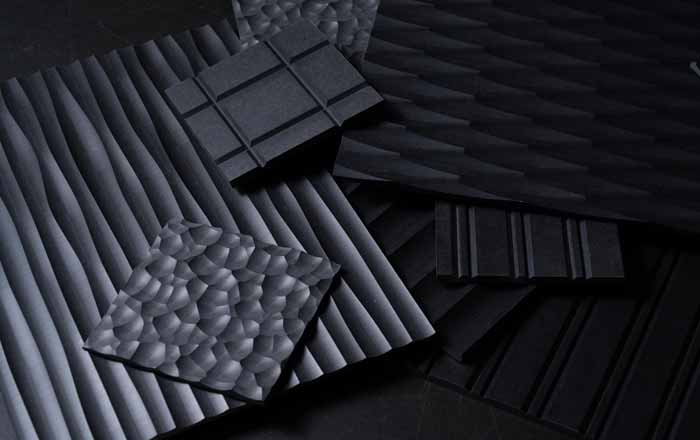

Designers may already be familiar with the speckled and often colourful surfaces from the Finnish brand Durat, while Dutch makers Plasticiet create their own recycled plastic sheet material – both of which are designed with future recycling in mind. The most recent addition to the Surface Matter offering is a lightweight acoustic material from French manufacturer Pierreplume, and a new departure from exclusively solid surfaces, although still saves waste from landfill.

Representing these specific brands makes them a part of the wider sustainability conversation, which is clearly being driven, at least in part, by consumer-led thinking. Although Scott is wary of attempting overly simplified or definitive answers to the problem, “We’ve noticed a steep rise in the number of clients and people within the industry asking us what we think the most sustainable materials are and we always say the same – there are none.” On the surface, Scott’s stock response may seem defeatist, but the follow-up shows a far more constructive and nuanced mindset, “It’s important to remember that all materials have an impact, so it’s actually about how you specify and use them that can really create a positive impact.” With a career-long insight into the specification market, Scott has made helping specifiers a cornerstone of the company, and simply supplying a piece of material is never the only service the team provides. The same rigor and generosity of knowledge and information sharing are assigned to every inquiry, and this consistent approach pays dividends for the prospective client and their project, in addition to reducing the environmental impact as much as possible.

“I have felt a nagging sense of responsibility from the start – I’m ultimately responsible for all of these materials that come in and go out of our control. It’s always been my mission to ensure that we can minimise the inevitable impact at every link in the chain, including the waste stage.” This sense of duty was at the heart of the decision to set up the new warehouse space in Rye, although a need for increased autonomy in the distribution of their materials was another catalyst for the move. As a third-party logistics, the team had been reliant upon others to get the majority of orders to site. But one fateful error that saw a pallet of 50 sheets of Richlite travel to Scotland, instead of just a single sheet, was the final straw back in 2021. “It highlighted some major flaws in the existing distribution methods, as well as our own business model. We knew we needed to make a big change and take matters into our own hands, using care worthy of quality materials.” Having sourced the space, Scott took it upon himself during the initial lockdowns to start fitting out the unit. Months of back-breaking work, a forklift truck licence, and a great deal of investment later and the unit was taking shape, all he needed now were people to work there! In stepped George (Warehouse Manager) and Gareth (Logistics Manager), both of whom welcome me to the space with a clear sense of pride.

I’ve been in a lot of warehouses in my time, and I have seldom seen one so tidy and clearly well organised. As I enter the huge roller-shuttered door, I am instantly struck by the scale of the vast cantilever racks that flow from floor to ceiling across the space. Almost every shelf contains a palette on top of which are stacks of sheet material, which on closer inspection I note are neatly arranged by material type and colour. Toward the centre of the space resides the ever-essential electric forklift as well as an equally useful Vacuum board lift, which I am excitedly allowed to have a go on (having gone through the all-important safety briefing). To my right, I note a looming but nicely detailed box-within-the-box clad in black corrugated metal. Built locally and in part by the team themselves, it spreads across three stories, offering office, kitchen, toilet, meeting, and sampling spaces, as well as a table tennis desk complete with inlaid Durat. With a view across the warehouse from the vantage point of the open-topped, and once again neatly assembled sample deck, you get the sense of a well-oiled machine.

“We like to call it Distribution 2.0. We’ve taken everything we’ve learned from the old ways and tailored them to fit our client’s needs while developing better, more ecologically friendly practices.”

The fruits of their labour are starting to ripen with signs of genuine progress – not least in a recent B Corp certification – but also in how they approach the after-life of the materials they send out. Indeed, another notable detail found in the warehouse is a series of open-topped crates, each containing varying amounts of materials chunks, shards and offcuts. I take a closer look at the side of the tallest crate filled with brightly coloured shards and spot a label. It is headed with the Material Rescue branding, and amongst other things, it states the material type, in this case Durat, as well as a set of dimensions.

“They’re collapsible crates,” Scott tells me, “customers are invited to select how many they wish to be sent with their order and when they’re done, they can fill them with their off cuts and we collect them.” But that’s not the end of the process. The team then sorts the materials into separate crates according to material type, size and colour. “Each label states the minimum size available of each piece,” he selects a fairly sizeable lump from another crate and adds, “so if a designer or maker requires smaller pieces as opposed to a full sheet they can order this knowing that, as this label states, there is at least a 300×300 piece available within it. And any additional offcuts are theirs, or can be sent back to us of course.”

This closing of the loop takes time and work on the team’s part, but Scott is quick to point out that there is great value in this approach, “Reuse is always a better option than recycling because it uses less energy and resources, and as we’re finding, there is a demand for these smaller pieces of our materials.” Creating value works both ways though, and this methodology does create another revenue stream for Surface Matter, but pricing is relative to the original sheet price, making these previously unusable pieces as affordable as possible. It is also important to note that everyone in the chain can prosper as Material Rescue is in fact a buy-back scheme based on the weight of the material crates. Incentivising the scheme can only help increase the chances of their clients getting involved, although this approach isn’t a novel one. As Scott explains, “This isn’t a new idea, none of it is. Durat has been buying back waste material at a fair price for years. Again, we’ve just taken some of the best ideas we’ve discovered and knitted them all together.” Durat has also been recycling its products since the start, and this is another proven positive that Surface Matter are borrowing from them. The colourful content of largest Material Rescue crate consists of pieces that are too small for reuse and will one day go back to Finland where they will be shredded and transformed into a limited edition run of uniquely speckled sheets. Clients are even invited to send back all of the essential plastic and timber packaging their sheets are sent in, which are reused in turn, or go through a similar process.

Baking a cycle of reclamation and reuse – as well as recycling – into the system of material supply feels like a step in the right direction, and seeing it in action shows that coupling the inclination with a bit of hard work can make ecological and economic sense. Although the speed and attention to detail with which Scott and the team have created this logistics hub shows the drive they possess, something Scott attests to a very clear desire: “we want to use the full potential of all of these amazing materials.” The future success of their ambition has been built in at the planning stage too, with the foresight to earmark a neighbouring unit with the landlord when taking on the current lease. So it’s safe to say, there’s more to come from Surface Matter.

For even more visual insight into my trip check out the Design Insider Instagram post @designinsiderlive