Q&A: SUSTAINABILITY LEADERS – EGGER

Following on from our previous Sustainability Q&A articles, Design Insider is thrilled to welcome Sarah Dunn, Environmental and Energy Manager at EGGER UK. We found out about EGGER’s sustainability journey, the beginning of it all and the future of sustainability at EGGER.

Could you begin by introducing our readers to Egger?

EGGER is a leading international wood-based materials manufacturer, founded in 1961 by Fritz Egger Senior. We remain family owned, and produce products for commercial and residential projects in the furniture, interior design, building and flooring industries.

Product highlights include Melamine Faced Chipboard (MFC), Laminate, and Structural and Laminate Flooring. Our diverse range of products are found across the world in offices, retail spaces, restaurants, bars, hotels, student accommodation, kitchens, bathrooms and bedrooms.

Well known for investing in new, innovative products, we also offer free online design services including Virtual Design Studio, Worktop Visualiser, EGGER Decorative Collection App, Flooring Visualiser, Virtual Samples and more.

The EGGER Decorative Collection 2020-22, EGGER Worktops Collection 2020, EGGER PRO Flooring Collection and EGGER Advanced Structural Flooring are available nationwide via a network of distributors and retailers.

When did you first begin to address sustainability within your business? What were the first steps?

Sustainability has been at the heart of EGGER since it was founded in 1961. To create ‘More From Wood’ has always been our key principle, and ensures sustainability is given the highest priority. Our founder, Fritz Egger Senior, is famously quoted as saying “Wood is far too valuable to just throw it away!”

Our environmental objective is to produce quality products that are fit for purpose, with as little impact as possible on the environment, in terms of waste, pollution and energy usage.

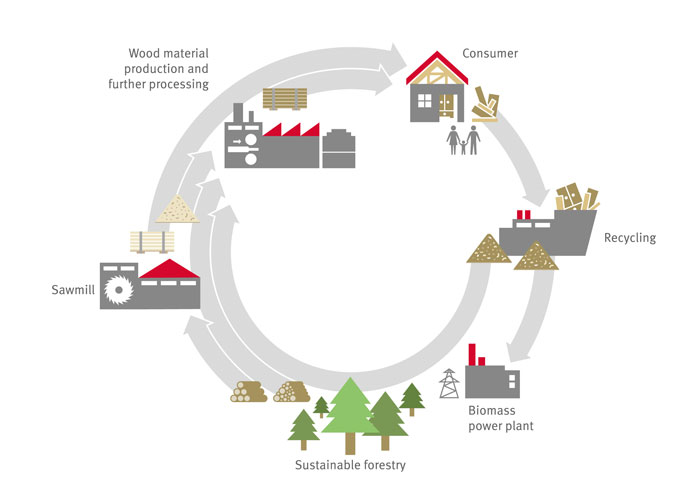

We operate a closed loop environmental cycle across all 19 of our sites worldwide. By adopting this method, the environment benefits through the efficient use of wood materials. This includes forestry, recycling, manufacturing and renewable energy processes, all of which reduce our environmental impact.

Could you tell me about your use of sustainable forestry and the other ways you have addressed material sustainability?

Our dedicated Forestry team ensure the responsible sourcing of raw material. They have well established relationships with suppliers, and focus on the future of forestry to guarantee supply for generations to come.

We use round wood, sawmill co-products, and recycled wood to produce our wood-based products, and are committed to developing new ways of reclaiming and recycling the materials used in production.

To help achieve this, our subsidiary company, Timberpak Ltd, is responsible for sourcing and managing our recycled wood requirement. It makes a valuable contribution to improving the environment through its recycling processes by utilising all timber waste material and creates a market for the items that would otherwise be burnt or sent to landfill.

Chipboard, our signature product, is made up of 40% co-products from the sawmill (waste hack chips and sawdust from the processing of sawn timber), 40% recycled wood (sourced via EGGER Timberpak) and 20% round wood (forest thinnings and the top part of the tree that the sawmills are unable to process).

Sustainability is a key focus across your business; can you tell me in detail about your sustainable production?

At our plant in Hexham, Northumberland we implement the following:

Raw material: We source raw material harvested from forests certified according to PEFC and FSC, and only buy timber from verified suppliers, in line with the EU Timber Regulation (EUTR),

Recycled material: As the largest user of recycled timber in the UK wood panel industry, EGGER Timberpak provides 95% of our recycled material requirement, offering the construction, manufacturing and waste industries a sustainable solution for waste wood.

Biodiversity: To maintain and promote biodiversity, 13,200 native trees surround our site in Hexham. Nest boxes for house martins and sand martins have been installed to stop them nesting in the raw material. Beehives have also been installed to stop bees from swarming.

Production: Each year our Biomass Energy Plant at Hexham saves 71,000 tonnes of CO2 by burning wood residue that can no longer be used rather than natural gas. This generates hot gas and renewable energy to heat the thermal oil used to power production and office buildings.

Water: Our log yard operates a Sustainable Urban Drainage System (SUDS). It is on a slight gradient to ensure any rainwater is channelled through a reed bed, which cleanses the water of any wood residue before entering the river.

Emissions: Our Wet Electrostatic Precipitator (WESP) ensures that emissions to air from production processes fall well within the statutory limits. This technology is the most environmentally efficient way of removing moisture, as condensing it would involve a huge use of energy. To comply with environmental legislation, emissions to air are routinely monitored and water samples are taken regularly.

Waste: The majority of waste material generated during production is re-used in production, either as raw material for board or, if no longer suitable, to fuel the energy plant.

ISO Certifications: We comply to the following ISO standards: 14001:2015 environmental management system, 9001:2015 quality management system, 38200:2018 custody chain of wood and wood based products and 50001:2011 energy management systems.

Products: Environmental Product Declarations (EPDs) and EcoFacts are available for all EGGER products via egger.com.

What is your next step?

We are committed to achieving our ‘zero waste to landfill’ aim, and continue to look for ways to reduce our energy consumption. We have set ourselves ambitious targets in the UK, but

by 2030 we plan to have reduced our energy usage by 10%, which would also reduce our C0²levels by 15%.

As a Group, we are committed to sustainable development across the whole business. Among other things, we will continue to:

• Set company objectives that align with environmental goals of the UN Global Compact.

• Expand the environmental information and increase transparency available about our product range

• Constantly analyse our upstream and downstream emissions

• Promote the EGGER Supplier Code of Conduct.

• Trial new production methods that include a higher percentage of recycled material that does not compromise on quality.

Contact EGGER UK Group through BCFA Product Finder.

The BCFA Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news and design trends.