Q&A Sustainability Leaders – Roman

Roman has been designing and manufacturing showering solutions for over 36 years, and is the UK’s largest shower manufacturer with a strong presence in over 60 International markets. All Roman products are proudly designed and made in Britain, offering the ultimate in quality, precision and craftsmanship. Roman’s diverse and versatile collection of products encompasses something for every style and shape bathroom – no matter what the budget. The reputable and well established UK brand supplies showering products all over the world including Shower Enclosures; Bath Screens; Wetroom Panels; Walk-in Enclosures; Anti-Slip Shower Trays; and Solid Surface Fabrication of basins, vanity units and bathroom structures. We are thrilled to continue our Sustainability Leaders series with David Osborne, CEO of Roman.

Why is it important that your products address the circular economy?

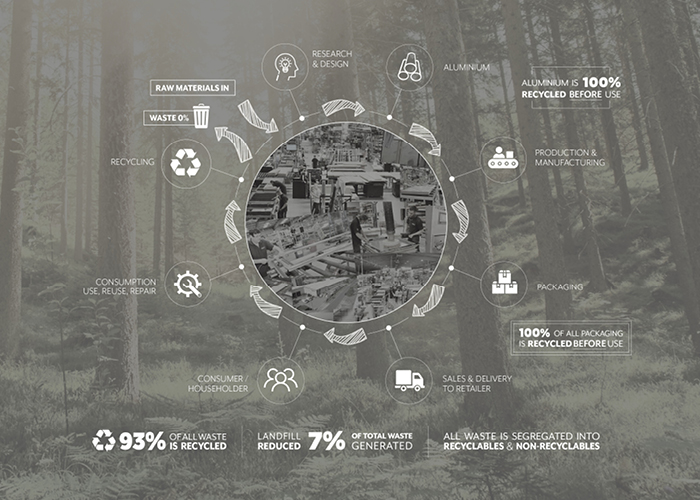

Roman’s product design is firmly based around the principles of the Circular Economy and embedded in material selection and operations – with all aluminium and packaging manufactured using 100% recycled material before it’s used in the manufacturing process. We see the tangible science behind the Circular Economy as the basis for future carbon taxes – as the key UK manufacturer, we need to embrace the Circular Economy as a benefit to us and our customers in the long-term.

Are any of the materials you use recycled or recyclable?

Roman has its own aluminium extrusion and anodising plant. Every piece of aluminium extruded uses only already recycled material – our packaging on every product is entirely cardboard and once again 100% recycled before we use it. All our glass and brass also feature very high levels of recycled material – our toughened glass will become 100% from recycled glass during 2021; and our solid surface shower trays, vanity tops and other fabrication based products are very durable and at the end of their life, they can simply be reground into their original form and re-used at their original value.

How do you ensure the provenance and traceability of the materials you use?

In line with CE and UKCA Marking, all Roman products are fully traceable for a minimum of 10 years. All products are digitally photographed during the final stage of packing and issued with their own unique product number – this ensures traceability to the production line, the date, time and operators. This traceability is also being extended to cover raw material batches and be supplier specific. All Roman products are made in Britain at our 400,000 square foot manufacturing facility in County Durham – and exported around the world.

How do you control your supply chain and chain of custody?

We have a very close working relationship with all our key material suppliers and our vendor rating system covers all aspects of their capability and operations – most notably of course their environmental credentials. We also assess their corporate social responsibility and their strict adherence to modern slavery regulations. We are constantly setting and evolving sustainability targets for our supply chain and sharing our own achievements and initiatives with our supply chain. Our business model is based upon environmental and economic sustainability – we employ over 250 people in the UK.

You have a huge target to be end-to-end carbon neutral by August 2021, how will you achieve this?

As a British manufacturer, sustainability has permeated across every department and process at Roman over the last ten years – and as a multi-generational brand, we expect to be fully accredited as Carbon Neutral by August 2021 at the latest. This has been a rigorous and thoroughly audited process which covers the full end to end scope of all Roman’s operations. We are constantly introducing new ideas and initiatives at all levels to ensure that change constantly evolves and that all employees know that they have a part to play in environmental change. Roman’s research and development team is made up of 6 experienced individuals from a variety of design disciplines and have undertaken specialist design for sustainability courses.

Attention to detail has been key, could you give me some examples?

The amount of detail in our sustainability programme is immense and we can offer some incredible data to our customers. As an example, we measure the litres of water used per tonne of aluminium extruded in our aluminium plant for two major International Hotel Groups. The water leaving our aluminium plant is cleaner than the water that goes in. The extrusion presses are all modern, super-efficient and run on gas which we can control and measure precisely. The chemical tanks for anodising are constantly rebalanced so they are never purged. We literally measure everything that we can….

Do you offer an end of life scheme?

Due to our design process and the material selection of our packaging and all of our products, they are all extremely easy to recycle at their end of life – and intended for reuse at the original value and purpose. Our service backed guarantee is termed as “Truelife” lifetime due to the quality of the materials, mechanisms and build. In addition to this, we offer an end of life scheme for our retail and project customers so that Roman products can be recycled for future use.

Did I hear that you have also been busy recycling cardboard this year?

Our installation division consists of over 50 field engineers who install Roman products for some of the major housebuilders in the UK. In addition, they also install all of our mock up rooms and displays to ensure the desired operational quality is achieved and eliminate the variable of installation. To comply with on-site waste protocols, we return our packaging back to ourselves post installation. Last year, we recycled over 600,000 square metres of cardboard back into our supply chain from building sites and displays.

How will your work in sustainability enable you to meet the government’s upcoming targets?

Being fully accredited as a Carbon Neutral company will put us in a very strong position as we move forward. We have no doubt that Carbon Taxes are emerging and that tender processes will increasingly include a carbon footprint qualification so this will give us a major commercial advantage over imported goods. The government is clearly going to be very focused on dramatically reducing landfill and they will firmly focus their efforts on products and materials which offer landfill as their only option for end of life disposal. Due to our huge emphasis on the Circular Economy there is no part of any Roman product which cannot be easily recycled and used back at its original value and purpose.

What does your work in sustainability mean for your customers?

Many of our customers (and particularly the hospitality sector) are already extremely focused on their own sustainability programmes and on their own Carbon Neutral or Carbon Zero status. We are seeing it emerge as a significant driver in hospitality and design so clearly we will rank highly in any such comparison or portal system. Whilst we are competitive with comparable products anywhere in the world, it is encouraging to already see that environmental credentials are fast emerging to be as important (or more so) than price alone. Sustainability will only get more important for us all.

Contact Roman through BCFA Product Finder.

The BCFA Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news and design trends.