Regenerative Revolution: Heimtextil’s New Sensitivity Ushers in a Sustainable Future in Textile Innovation

When it comes to contract textiles, few trade fairs match Heimtextil for its scale, scope and innovation. Organised by German brand Messe Frankfurt and taking place in it’s own exhibition centre, the event returned in January with an increase in exhibitors and visitors alike.

Heimtextil 2024

Some 46,000 guests from 160 nations passed through the doors, taking in the latest textile-based materials and trends supplied by close to 3,000 brands harking from 60 countries. No mean feat when considering the travel issues created by nationwide train strikes throughout the month (sounds familiar?)

Heimtextil 2024

This year the organisers chose the theme New Sensitivity for the show, emphasising a transformation of the textile industry through three increasingly more sensitive approaches to manufacturing. That placed a greater focus on the plant-based production of textiles, bioengineered natural ingredients and the use of technology to improve the life cycle of textiles. As well as a plethora of exhibitors found across the great halls, these themes were given a spotlight in the Heimtextil Trends stand, where UK-based design futures consultancy Franklin Till once again shared their insights.

Heimtextil Trends 2024

Their informative and inspiring exhibition brought together a range of designers and material-lad explorations, which the team feels answers the salient question of how we might collectively move beyond the existing usage of the term “sustainability”. Or at least begin to. In recent years, many big brands – not least those who make and pollute the most – have jumped on the bandwagon and used the term with little justification beyond boosting public image and retaining sales figures. As a result, it has reached a saturation point, which at the very least muddies the water, and at the more extreme end reduces the potential for positive impact upon the environment and ecosystems that inhabit them, including people.

What the team posits through their in-depth research and collective thinking is a fresh set of approaches and with them, a new and more rigorous, term to work with: ‘regenerative’. As the team explains,

“With human activities already causing major harm to the planet, current efforts around sustainability don’t go far enough to tackle the environmental crisis we are facing. Regenerative design is committed to putting back better – creating holistic creative practices that restore or renew resources, leave a positive environmental impact and help communities thrive.”

Heimtextil Trends 2024

During the event they proposed 9 principles, each one focused on the work of a specific designer or studio, which begin to open up the interwoven and integral possibilities of regenerative practice. The first titled Enriching Communities posed the question “How can we enrich the lives of the people producing our materials and products?” While this may feel like a step away from the immediate issue of environmental impact, the team, along with product designer Fernando Laposse posit that the social impact of manufacturing cannot be ignored – people are still heavily involved in production after all.

Enriching communities, Fernando Laposse

Working with local communities in his home country of Mexico, Laposse produces stunning design objects from natural materials, not least the agave plant. The cactus has long been farmed to make tequila, but modern techniques have begun to take their toll on the landscape. Laposse collaborates with the farmers, utilising traditional methods to grow agave in trenches that helps to capture water and repopulate fields, while fellow locals process the plant’s leaves, transforming them into Sisal and then his now trademark ‘furry’ pieces. While emphasising better working conditions and pay for his team, this considered form of design-led production regenerates both the social and environmental systems at play.

Replenishing the land, Ponda

The second principle focuses more squarely on our collective impact on the land, particularly the effects of modern industrial farming. By asking “How can we grow and harvest materials in a way that has a positive impact on the land?” Replenishing the Land seeks to highlight regenerative practices that rebuild organic soil matter, sequester carbon and retain water more effectively in the natural landscape while reducing the use of harmful pesticides and fertilisers. UK materials science company Ponda is a leading example of this, using plant-based materials to create planet-positive textiles. In the case of BioPuff®, they use regenerative agriculture to harvest the fuzzy tops of bulrush plants to form a fibre filler in the use of insulation.

Preserving heritage, Norlha. Photo by Nikki Mcclaron

The team’s research into indigenous practices, not least in discovering mother-daughter duo Norlha, led to the question “How can we utilise knowledge from ancient material and textile production, and ensure these skills continue to thrive?” A celebration of local cultures and craftsmanship, Preserving Heritage pushes us to reconsider our outlook on rapid industrialised manufacturing processes and look to the ancient wisdom of such communities, which have proven over vast expanses of time to be ecologically sound in their approach to making. Norlha employs 130 local Tibetan people who are highly skilled in the production of felted yak wool, a native alternative to cattle that can have devastating effects on the land and our atmosphere.

Restoring biodiversity, Jess Redgrave, Climafibre

Restoring Biodiversity talks of a multispecies approach that seeks to break away from human exceptionalism, the effects of which we are witnessing in the destruction of natural habitats and the threat (and reality) of extinctions. Fast fashion is a particularly damaging sector within modern manufacturing and consumption; something that UK-based Climafibre is facing head-on. Led by multidisciplinary designer Jess Redgrave, the primary material protagonist in the team’s work is sunflowers, which are “A species that can be grown globally and require minimal intervention, fertilisers or watering, sunflowers’ resilience offers huge potential for climate change adaptation.” When rotated with other crops they also help to regenerate the soil and by using the entire plant to create fibres and dyes, they go a long way in answering the pertinent question, “How can we revive plant and wildlife ecosystems damaged by modern material supply chains?”

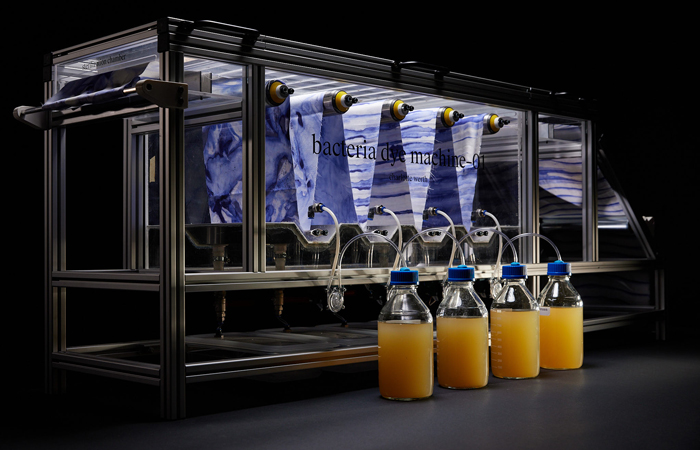

Biological fabrication, Charlotte Werth

Technology also plays a leading role in the move towards regenerative practice and the impact of scientific and design crossover cannot be underestimated. The work of MA Material Futures at Central Saint Martins graduate Charlotte Werth underlines this and forms the basis of the Biological Fabrication principle. Her answer to the conundrum “How can we combine natural materials with high-tech synthetic innovation to create alternative material supply chains?” is answered with bacteria, and the highly productive process of producing a natural purple pigment used to dye fabric. Requiring less water than synthetic dye processes, Janthinobacterium lividum bacteria are grown in a bath of yeast extract, salt, protein and glucose within Werth’s Bacteria Dye Machine. It incorperates UV light to sterilse the fabric, which is itself luxury deadstock that would ordinarily be discarded.

Naturally abundant, keel labs yarn. Image by Ryan Duffin

Recognising our reliance upon polymers, Keel Labs explore the potential of naturally sourced and plentiful alternatives to petro-chemical options that have dominated the market and led to mass destruction and countless waste. Kelsun™ is a seaweed-based yarn created from an abundant polymer found in kelp and the star of the Naturally Abundant principle. While Tarkett look to existing waste streams to form new yarns for their DESSO carpet tiles, with a genuinely circular approach to manufacturing. Chief protagonists of Reclaiming Material, the brand has it’s own carper recycling centre that operates under the ReStart® banner. Products themselves are made from post-consumer yarn ECONYL®, which is applied to their EcoBase® backing and can be taken apart and recycled effectively at the end of the products lifecyle.

Reclaiming material, Tarkett, Franklin Till

Radical transparency, Haelixa Materialien

Once again, science and technology come into play with the work of Swiss-based Haelixa, who go some way in answering the question posed in Radical Transparency, “How can we create traceable global material supply chains that tell the full story of

material life cycles?” Traceability is the key here, with the companys doctor-led team physically applying DNA to raw materials so that their footprints and life cycles can be tracked and measured. Utilising a unique spraying system that causes no harm to product or consumer, product and brand information lives on the surface throughout the products lifecycle and can be read and verified by forensic PCR technology.

Cultivating localism, Atelier NL. Photo by Hanneke Wetzer

Locality and provenance are the drivers of Cultivating Localism, which suggests alternatives to environmentally-impactful globalised transportation of materials and goods. Eindhoven-based studio Atelier NL, “honours cultural heritage and inspires appreciation for the planet’s resources, using locally-sourced wild sands for glassmaking and clay for ceramics.” Their tableware embraces non-standardisation by offering subtle variations of shade, that are created as a result of the natural properties of each provisional raw material used in the production process. The story of where and what each piece is made from lives on the surface, allowing for a deeper connection to its place of origin, while greatly reducing the distance it needs to have travelled in the process of production.