Showering at Sea

Roman have been manufacturing Shower Enclosures in Britain for over 35 years. They are active in all UK market sectors and internationally they are particularly prominent in the hospitality sector. Whilst their design and specification teams are used to interesting bespoke designs, probably the most challenging tend to be for cruise ships.

In most Hotel design scenarios Roman might offer a selection of solutions for the client, or an alternative installation method. No such luxuries generally exist on a cruise ship specification as space is normally to an absolute premium; there is only one design solution; and the fixing points are pre-determined and extremely difficult! Much as Roman’s world is focused on showering, in reality the team know that Shower Enclosures are one of the last bathroom fittings to specify – especially on a cruise ship. Roman are generally presented with a space and then required to offer a solution – and fast. As is the nature of cruise ship design, the bathrooms are compact but fully functional and luxurious. Opening space for Doors is limited, the products must be durable and easy to clean – whilst of course looking good.

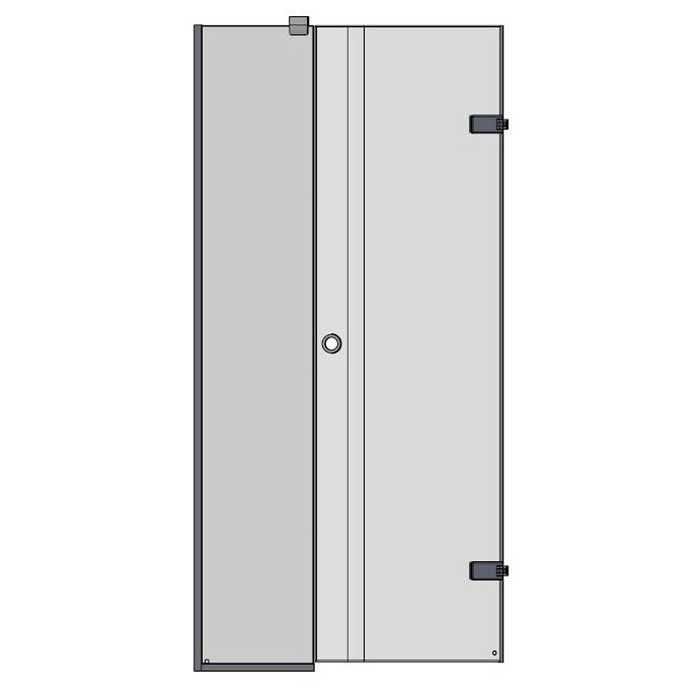

These images highlight the design problems that the Roman designers encounter. The designers have maximized the active showering area but the layout of the bathroom and walls mean that the shower is not a recognizable shape or size – and clearly walls cannot be moved. Therefore the solution was to make a special sized Shower Tray in Roman’s solid surface moulding plant. The moulds are quick to manufacture and relatively low cost due to the volumes involved. The RomanStone material is naturally anti-slip so is ideal for hospitality and cruise ships. The Shower Enclosure is essentially missing one side due to the wall and also the fixing point for the Door is at 45 degrees. This required Roman to design a new wall profile in our aluminium extrusion plant which is again completely bespoke to the project.

Roman operate with eight ranges of products and have built up a huge array of hardware over the years so meeting the rest of the requirements was straightforward. However, the next challenge was once the drawings were signed off, to have a completely functioning Tray and Enclosure in a mock up room in Italy within two weeks…That is when manufacturing everything in the UK comes to the fore…

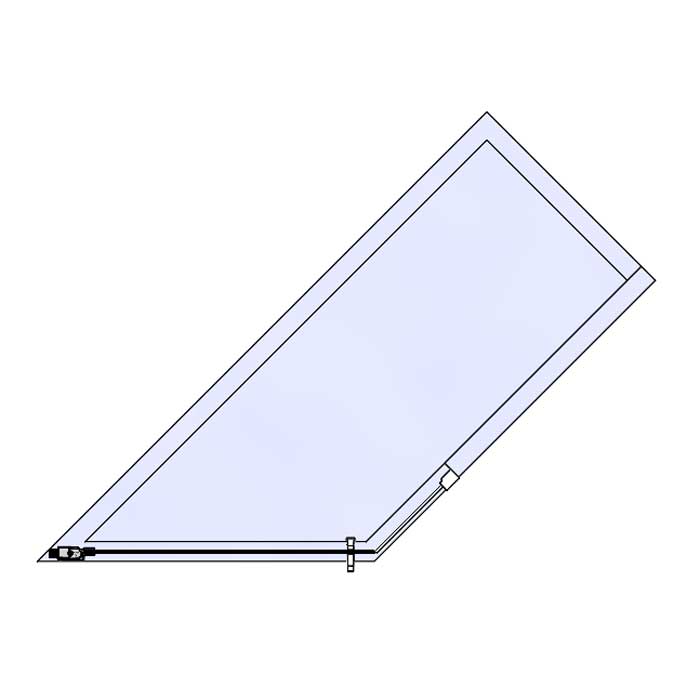

These images show a simpler solution to a not too dissimilar scenario where a special, very tight, bend on the toughened glass was the answer. Whilst the Tray, glass, extrusions and hardware might be the most visual aspect of the products, probably the most intricate and time consuming in design terms are some of the smaller detailing such as seals, capping, bracing and injection mouldings. Without the evolution of 3D printing, the chances of a fully functioning prototype delivered in two weeks would be all at sea.

Whilst providing bespoke design solutions might be challenging for our design, specification and production teams, they do serve to highlight the benefits of manufacturing capability in Britain. In addition, such opportunities aren’t everyday sales, the volume rewards are excellent and the nature of the solutions preclude low cost imitations. In short, cruise ships are an excellent market to be involved in and the clients genuinely appreciate the capabilities required which is key for customer retention and future recommendation.

Contact Roman through BCFA Product Finder.

The BCFA Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news and design trends.