Step by Step: Morgan

During December Design Insider will explore the production processes behind our members’ most unique and innovative designs.

We began look at the processes used by Morgan when creating the solid timber Oslo Collection.

The Oslo Armchair is one model within the Oslo lounge and dining collection which embraces its simplicity with light elegant design.

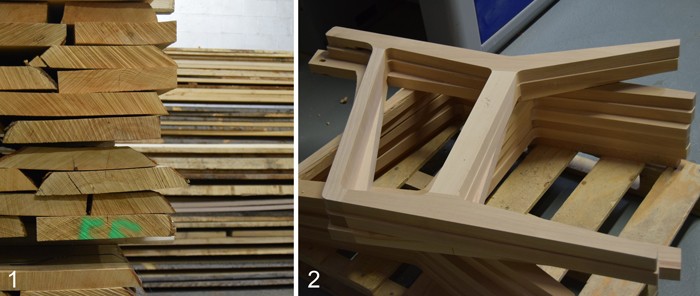

1. The Yard: ‘We start with trees’. All of our furniture begins life in our yard, where timber arrives as raw planks, sourced from FSC sustainable sources.

2. The Mill: Through our mill we use a range of both traditional and advanced modern machinery. The Oslo chair pictured relies heavily on our CNC milling capabilities.

3. Assembly: Assembling frames by hand remains a fundamental part of the Morgan process, furniture arrives in a variety of parts from the mill and each unit is accurately assembled by hand.

4. Polishing: Our skilled team polishes every timber frame; this process gives all of our timber products a high quality matt lacquer finish that protects the frame for years to come in any contract environment.

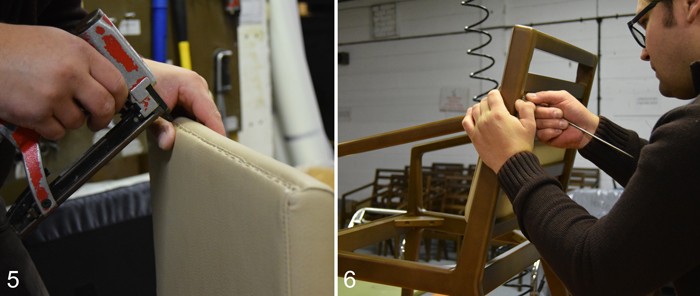

5. Upholstery: Whether it be a full sofa or a simple seat, our skilled upholstery team cut, sew and upholster in almost any contract fabric or leather that the customer requires.

6. Despatch: Our Despatch area is where any final assembly takes place, but more importantly every item is individually inspected against our quality criteria before being transported in our own fleet of vehicles.

In August 2016 Morgan produced highly bespoke and prestigious solutions for the newly designed Champions’ Room at The All England Lawn Tennis Club (AELTC), Wimbledon. The Champions’ Room is the exclusive hospitality venue for the Centre Court debenture holders at Wimbledon to provide an elegant and relaxing break with fine dining or afternoon tea. Read more about the project here

Contact Morgan

We hope you have enjoyed being invited behind the scenes, let us know in the comments below or on Twitter @DesignInsider1