Sustainability at Morgan with Managing Director, Paul Jones

Paul Jones is Managing Director at Morgan, a British contract furniture designer and manufacturer. Morgan are a design-led company, striving to create truly original, high-quality furniture through passion, care, design, integrity, experience, craftsmanship and an unfaltering dedication to quality.

Paul’s history with the company started in 1999 when he accepted an industrial placement as part of his university studies. It was also his introduction to the world of manufacturing.

After spending 11 years as Production Manager, devising and driving his award-winning Lean and Continuous Improvement Programme, Paul stepped away to work in consultancy and advisory services. This gave him the opportunity to gain experience across a range of manufacturing sectors, using the same lean principles, to build up my knowledge base.

Paul returned to Morgan in early 2019 as the company General Manager before taking on his current role as Managing Director. Design Insider spoke with Paul as part of our UK Made campaign in March 2021 which you can watch here and we leapt at the opportunity to ask Paul more questions as part of our current Sustainable Materials campaign.

Addressing the sustainable impact of the business is not new to Morgan, what major achievements have you already made?

Most importantly, I’ve prioritised the idea that goods and services should be produced in ways that do not use resources which cannot be replaced or which damage the environment. This guides everything we do.

Sustainability and LEAN principle objectives work hand in hand. If an organisation claims to take sustainability seriously, it must also be seen to have LEAN principles at its heart. If it doesn’t, I would question their understanding of sustainability, which is, simply put: To provide goods or services demanded by the customer using only those resources that are absolutely necessary.

Importantly, this includes services. It’s a common misconception that LEAN only applies to manufacturing processes. However, our Customer Service Department is as focused on LEAN as our Manufacturing Team.

Therefore, sustainability and LEAN philosophy can only succeed if the organisation has the culture to truly embrace it and this, in my experience, is where many companies fall short.

What are the key initiatives you have instigated at Morgan which will enable you to meet your sustainable goals?

Our drive to maximise sustainability throughout the company began almost twenty years ago when we started implementing LEAN principles. Arguably one of the most important principles is continuous improvement, which is embedded throughout all we do. There are always areas in which we can do better, and no change is too small to implement.

In our polishing department, we’ve reduced gas consumption by 95% in the last ten years and offer water-based and non-VOC finish options. Where upholstery is concerned, we give fabric off-cuts and roll ends to a local charity, while foam is pre-cut to minimise wastage, with off-cuts returned to the supplier for recycling. We also offer a reupholstery service to help our clients minimise waste. Similar consideration has been given to our heating, water usage, packaging and more.

Can you give examples of how your Sustainability Strategy has directly impacted the production of your furniture?

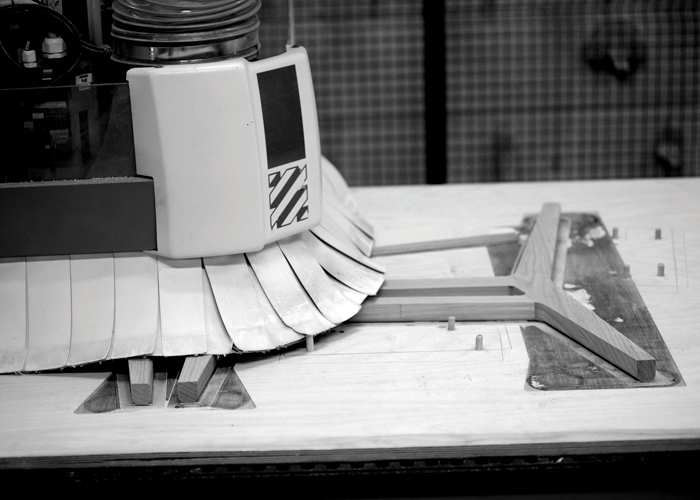

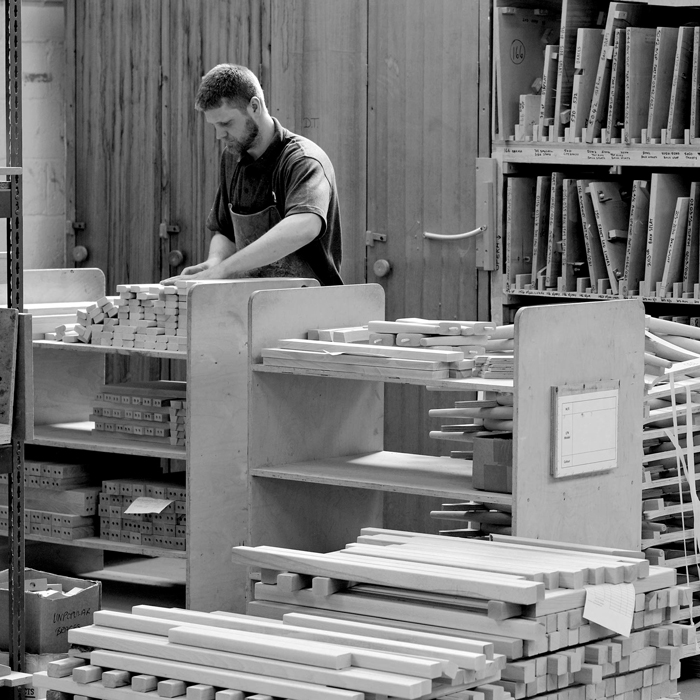

A key LEAN principle is to react to the pull of customer demand only, i.e., not manufacturing to stock but only to order. Being a truly British manufacturer, we start with trees, only consuming resources when absolutely necessary in order to satisfy specific customer demand.

We all know that accurate forecasting, especially more recently, is impossible, but manufacturers with heavily dependent overseas supply chains aren’t able to offer a 6-week lead-time without holding lots of costly stock, consuming warehousing resource and fuel to deliver, in the hope that their forecast is correct. Morgan’s UK supply chain, built up over decades, is key to manufacturing agility, allowing us to manufacture to order in the truest sense.

Our sustainability strategy also gives us more freedom with design innovation. By not keeping stock to meet forecasted demand, we’re not stifled by focusing on selling what we’ve already produced.

Can you explain your ‘make once, make well’ approach?

Once we commit to a customer order, we want to ensure we deliver against our sustainability & LEAN philosophy, only consuming those resources that are absolutely necessary. To this end, we closely monitor every function across the business to optimise quality.

At Morgan, we talk about the process determining the output. In other words, the defined process which people are trained against should deliver the required output. If the output isn’t what’s expected, we ask if the standard process was followed. If the answer is yes, then there’s a problem with the process.

It’s important not to default to pointing the finger and blaming individuals, because as an initial conclusion, this will almost always be wrong. It also risks people hiding opportunities for improvement.

Every function within Morgan has a target to deliver against and an accompanying simple visual report to show progress in line with the strategy deployment. For example, our Customer Service Department assesses their daily plan with a red/green rating system. If any elements are red at the end of the day, they will assess the reason, concern, cause and countermeasures to prevent reoccurrence. If they’re green, it’s an opportunity to identify strengths we can build upon and share best practice.

At Morgan sustainability is addressed through every member of your team, can you tell me more?

When we are setting the plan, including precise goals, actions and timelines, in order to achieve our mission, we involve department team members who are best placed with their specific knowledge and experience to explore the ‘how’.

Our strategy directly impacts all functions throughout the business, so our team can see a clear link between their activity and the achievement of the strategy, helping them feel a part of our business development.

Measurement is important, particularly for our dedication to continuous improvement, so we run a voluntary employee survey which helps us understand if this process is having the positive impact we want it to.

How will you continue to address sustainability in the future at Morgan?

We will continue to improve through the actions and ethos described above, underscored by innovation, and through our continued dedication to deliver our sustainability strategy. Further, we use external verification, such as through ISO 14001, to ensure certified commitments are delivered.

Sustainability is such an inherent part of Morgan that as long as we are developing as a company, we are addressing our responsibility to the environment.

Contact Morgan through BCFA Product Finder

The BCFA Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news, and design trends.