Sustainability; The Fibre of Camira

Last week the world’s press reported on COP21, 2015 Paris Climate Conference, where governments representing 195 countries pledged to limit global warming to 1.5C above pre-industrial levels. The future achievement of this target will affect every manufacturing facility, business and household in the UK.

Alys Bryan went to visit UK textile Manufacturer and BCFA member, Camira to see how a company can achieve these environmental targets.

Camira is a UK based textile manufacturer; they distribute more than 60 textile ranges to over 70 countries and produce an astounding 8 million metres a year. Last week I drove across the stunning Peak District National Park to Camira’s Meltham manufacturing facility in Holmfirth to meet with Paul Arnold, Camira’s Technical and Sustainable Innovation Engineer, and Jennifer Isles, Camira’s Marketing Communications Manager.

“Ray had had an environmental epiphany after reading Paul Hawken’s book “The Ecology of Commerce” and made it his mission to create a fully sustainable, then restorative company.”

Jennifer began by explaining to me how Camira’s environmental ethos was born; ‘Sustainability is part of Camira’s culture and DNA… Prior to becoming Camira we spent nearly 10 years as part of the Interface organisation, learning from the world leader in environmental best practice when the late Ray Anderson was at the helm. Ray had had an environmental epiphany after reading Paul Hawken’s book “The Ecology of Commerce” and made it his mission to create a fully sustainable, then restorative company. Camira continued this quest as an independent business…’ With this heritage it is easy to see why Camira feel that ‘Sustainability is our warp and weft; it’s within the fibre of Camira and at the heart of our culture and ethos.’

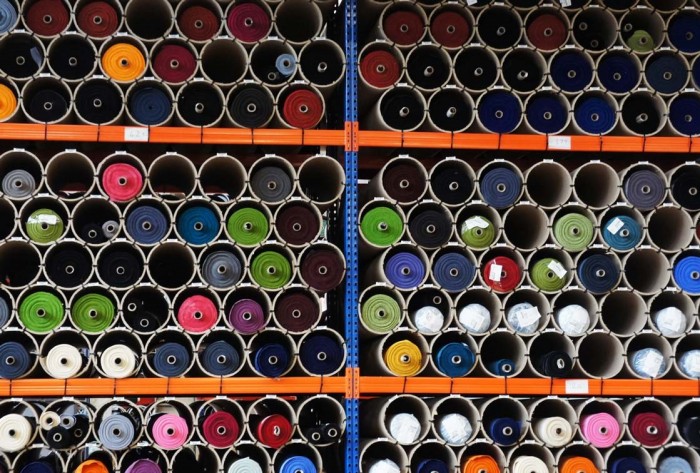

When I entered the Camira factory I was first struck by the size of the facility, then the hum and vibration of the looms but this was quickly forgotten when I began to read the prominently displayed company statements. It is immediately obvious that Camira’s ethos is not limited to their senior management team and Paul Arnold confirmed this when he explained how the company prioritises ongoing internal training across all departments; this enables every member of staff to be part of the continual development process and builds the company’s environmental ethos into a way of life.

“…builds the company’s environmental ethos into a way of life.”

When I spoke with Camira’s Director of Marketing Ian Burn for my previous DESIGN INSIDER article he explained that they achieved an impressive 98% service level to their customers due to their tight control and the ownership of their own supply chain. In fact Camira own UK facilities for spinning, knitting and yarn dyeing; this control not only facilitates an enviable service level but also allows for continuous research and development.

An example of Camira’s recent process focused achievement is their ability to maintain 0% landfill. In 2009 Camira sent 340 tonnes of waste to landfill: I asked Paul Arnold how they have been able to so radically reduce their landfill waste. In reply, Paul explained that through the company’s 2012-2015 strategy, every manufacturing process has been explored, unnecessary packaging is being removed or returned to the supplier, selvedge material is returned for recycling and, where possible, is part of a closed loop cycle to be used in one of Camira’s own recycled collections. I understand that the disposal of fabric remnants can be a burden for furniture manufacturers, by arrangement Camira are able to take back remnants of their own fabrics, which are then sent for recycling with the opportunity of entering a closed loop cycle.

“Camira are able to take back remnants of their own fabrics, which are then sent for recycling with the opportunity of entering a closed loop cycle.”

This year Camira has been awarded their second Queen’s Award for Enterprise: Sustainable Development. This is the result of achieving the targets they set themselves for continuous environmental development in their 2012-2015 strategy, and their achievements are exemplary!

0% Landfill is achieved through a rigorous strategy for recycling including the development of closed loop textiles.

Camira’s ‘Style with Substance’ publications outline their in-depth reasoning for selecting wool as their fibre of choice, these include wool’s prominent performance and environmental benefits, making it clear to me that at the core of their textile development is their understanding of materials. Camira’s spinning facility has enabled them to develop innovative yarn blends starting in 2005 with a four year research and development project on bast fibre fabrics in partnership with De Montford University which resulted in the launch of Sting, which is woven from a blend of wool and nettles. Other materials utilised within bast fibre fabrics include flax, jute and hemp. I was fascinated to learn that Camira grew their own hemp in Leicestershire; a further example of the company’s commitment to being in control of every element of their manufacturing process.

Camira’s extensive knowledge of the production of virgin materials is called upon when there is a demand for properties which cannot be provided by wool and bast fibres. Their understanding of polyester has enabled them to develop specific polyester collections, maximising on the material’s recyclable properties within a closed loop system, water resistance and flame retardancy whilst reducing the environmental impact. The X2 collection is Camira’s first closed loop collection, Paul explained: ‘In 2012 we worked closely with our polyester yarn supplier to return waste polyester yarn and woven selvedges to be re-extruded and then woven into fabrics with 25% “closed loop” content…The first product to incorporate this “closed-loop” recycled content was X2, a mélange effect version of our already recycled Xtreme range.’

“Currently 61% of the products manufactured at Camira’s main UK site are from natural or recycled raw materials”

Currently 61% of the products manufactured at Camira’s main UK site are from natural or recycled raw materials. When discussing the company’s focus on innovation, Paul concluded that ‘Product development combines with process improvement and supply chain integrity to create a powerful environmental proposition for key target stakeholders.’

Camira communicate their environmental credentials widely outside of their company, Jennifer explained the importance of communicating their credentials and the benefits to their customers, ‘Environmental angles are a point of differentiation not just for Camira, but our direct furniture manufacturer customers who leverage some of their unique selling points. Many manufacturers operate their own stringent environmental sourcing principles. Certain end-user clients likewise demand transparency and best practice, public sector tenders frequently require specific environmental standards, while interior specifiers sometimes push environmental fabrics through their own choice or due to client briefs.’

Camira’s moral ethos has been demonstrated through the implementation of their 2012-2015 strategy; their goals have been communicated throughout their business and to their customers, and in turn their achievements have been recognised at the highest level through The Queen’s Award for Enterprise: Sustainable Development. Perhaps we will see Camira leading the way in reaching ‘net zero emissions’, which experts say is required in order to achieve the COP21 pledge; I am certainly confident that Camira have shown us a model to replicate for sustainable UK manufacturing.

Please join the conversation on sustainable manufacturing within the contract sector by commenting below or by tweeting @DesignInsider1 and @AlysBryan