UK Made: How Curtis Furniture Leads the Way as a UK Manufacturer

As part of our spotlight on UK manufacturing, Design Insider sits down with Andrew Reynolds, Managing Director of Curtis Furniture, to explore how the Leeds-based company has grown into the UK’s largest specialist manufacturer of hotel bedroom furniture. From adopting lean manufacturing principles to championing local sourcing, Andrew shares the journey behind Curtis Furniture’s success and how its commitment to adaptability, sustainability, and quality sets it apart in the industry.

Andrew Reynolds, Managing Director of Curtis Furniture

Can you start by introducing yourself and your role at Curtis Furniture? What has been your journey with the company, and how does Curtis Furniture stand out in the industry?

I’m Andrew Reynolds the M.D. of Curtis. We started the company in 1997 from what had been Curtis Shopfitters. I remember in the first year placing an ad in the yellow pages to find work for the four of us and then found myself at a site meeting of 30 people for the refurb of a large night club. My background was retail clothing and I sat in the meeting thinking “I don’t really know what they’re talking about but that guy is a 42 short suit and that one is a 16 ½ collar shirt”

In those early years we made decisions about focus and that was part of the making of Curtis. Having had early links with Thistle Hotels, we decided to specialise in Hotel bedroom furniture and I am proud to say we are now the largest specialist manufacturer of hotel bedrooms in the UK. (and we still work with Thistle Hotels).

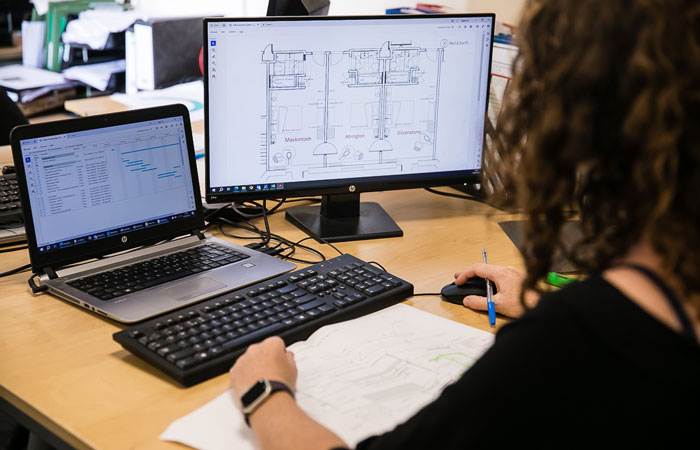

How do we stand out – we learned early on that making lovely furniture was just half of the challenge of looking after hotel customers. The often, unseen, element is the co-ordination of the process from quick quotes through to the often changing demands of a live installation. To handle this, each project not only gets a dedicated Curtis project manager but we also provide a fully employed Installation Manager to provide communication, management and presence on each site.

Curtis Furniture prides itself on its tried-and-tested processes. Can you explain how lean principles are integrated into your operations, and how they contribute to efficiency and quality?

LEAN is all about reducing waste – both physical in terms of raw materials or the less visible waste of time, it all costs. Our ongoing lean projects constantly review how we as a team reduce the wastes in the business. There is not a week goes by where we don’t turn a key element of the business upside down, give it a shake and look to improve it.

Lean manufacturing is often associated with reducing waste and improving workflows. Can you share a specific example of how these practices have benefited a recent project?

We recently completed a project at the Russell Hotel, marking a significant milestone as the first initiative managed under our LEAN manufacturing approach. Our primary focus was on enhancing quality, achieving “right first time” outcomes, and reducing lead times.

To meet these objectives, we introduced several key process improvements: streamlined operations in our machine shop; better control of work-in-progress (WIP) levels; enhanced documentation practices; visual management systems and OEE (Overall Equipment Effectiveness) tracking. These changes allowed us to release materials to the assembly shop more efficiently, ensuring parts were correct from the outset.

This efficiency not only freed up more time for subsequent production processes but also improved quality standards, reduced overall lead times, and enabled us to deliver on time and in full

UK material sourcing is a cornerstone of Curtis Furniture’s approach. Why is sourcing locally so important, and how does it align with your sustainability goals?

I think that the main reason we continue to grow is that we are here on the ground in the UK. Things go wrong but when they do we can react; not only because we are generally less than 4 hours from any site but because we manufacture right here in Leeds. In the same vein we want our suppliers here with us in the UK. Occasionally there is cost impact but this is tiny in comparison to not being able to deliver to a hotel on time, and of course it being far better for the environment in terms of our carbon footprint.

Hotel Bedroom furniture is BIG. It is heavy and space consuming so that from a sustainability point of the decision on where we manufacture is very simple. We make our furniture here in the UK and in doing so, do away with hugely expensive and carbon creating shipping of the furniture across continents.

With the majority of your materials sourced from the UK, how do you navigate challenges such as supply chain fluctuations or increased demand while maintaining high standards?

We work as a team with our material suppliers, many of whom have been with over ten or even twenty years. We talk to them all the time and we pay them on time which means they do their utmost to look after us.

How does UK-based manufacturing provide tangible benefits to your hotel clients in terms of lead times and adaptability?

As well the reduced lead times that our UK factory allows, we can also be far more flexible with our approach. For example, clients often develop a sample room and then review this room and build in the lessons learned for the roll out. The reality is that the sample room type may represent less than half the keys in the hotel. We recognise this and have developed systems that allow for new room types to be reviewed as the development rolls through the hotel. Being here in the UK gives us the opportunity to implement the new lessons learned quick enough to deliver the improvements during the fit-out.

As Curtis Furniture continues to grow, what do you see as the biggest opportunities and challenges for the company in the next 2–5 years?

The answer to both questions is the same. People. We have a team of fantastic people here who are committed to not only looking after our customers but also to constantly looking at the ways we can improve the way we do so and that is a wonderful opportunity for any business. The challenge as we grow is in recruiting and training more great people.

How do you plan to adapt to evolving industry trends and customer demands?

Investment & Communication. With regards to investment, beyond the Lean programmes we discussed, we are constantly investing in both new machines and also in technology that helps the team co-ordinate everything from fast quotations through to site QA procedures. With regards to communication, it is dangerous to guess what customers are looking for, so we spend time with them reviewing completed projects and discussing what they want from us going forwards.

Find Curtis on Supplier Finder

Supplier Finder is the UK’s only search platform for accredited suppliers of commercial interior furnishings.

At Supplier Finder, our mission is simple: to help you find the perfect commercial furnishing suppliers for your interior schemes and projects. We understand the importance of having confidence in the suppliers you specify and the products that bring your designs to life. That’s why each supplier featured on our platform is accredited through Commercial Interiors UK’s rigorous membership application process. This ensures that you engage with only the best in the industry!