Venue Tables: A Global Journey of Success & Collaboration

In anticipation of Broome Jenkins’ upcoming 20th anniversary as product designers, Design Insider had the privilege of sitting down with the company’s founder, Barry Jenkins. This insightful interview delves into the changing landscape of external design consulting, their perspective on the commercial furniture sector, and their exciting plans for the future. Barry shares his experiences working across diverse industries, reflects on the value of external design consultancy in the era of in-house design teams, and offers insights into their innovative approach, including the recent foray into manufacturing with the Venue Table range.

Join us as we learn more about Barry’s expertise and his vision for Broome Jenkins.

Barry Jenkins, Founder of Broome Jenkins

In the run-up to product designers Broome Jenkins’ 20th anniversary, Design Insider caught up with their founder – Barry Jenkins to discuss how being an external design consultant has changed, how they view the contract furniture sector and what they have planned for the future.

A privilege of working as an external designer is that you get to work across different industry sectors with a range of people who have skills and knowledge to compliment your own.

I have been lucky to work on a wide range of things from consumer electronics to Aircraft Interiors. I have also worked with some very interesting people, and as a business we have benefitted from collaborating with inhouse design and marketing teams. As a result, we have learned a lot and observed that no two companies are exactly the same, even if in the same sector.

FourFold, design by Broome Jenkins for Four Design/Ocee International

With the growth of in-house design teams, what do you value most about being external?

There is no doubt that the level of design awareness and design capability within client companies has increased, so that engagement between consultant and commissioner is much better informed than it used to be. This keeps designers on their toes, which personally I think is a good thing, as now more than ever we need to make genuinely useful, informed products as part of a drive towards greater sustainability.

Therefore closer collaboration between the various partners in developing a new product is even more important.

Hotbox 4 designed by Broome Jenkins for Hotbox

Being more sustainable is top priority for any manufacturing business. What part should or can designers play?

Reducing waste during the manufacturing stage and at the end of life is undeniable and accepted. However, given that developing a new product is experimental and explorative, and that success can come from failure, we should also consider how wasteful the development process can be, especially if it ends with no tangible outcome. It is vital therefore to avoid what is referred to as ‘mission creep’ by being highly focused when setting the brief and throughout the project. The R&D ‘investment’ should only be justified through a determination to address a genuine need and be committed to making a difference and not another commodity that becomes future landfill.

You talk about efficient R&D and being focussed, do you have an example?

One good example of being focussed, is our client Hotbox. Since 2019, we have been working with Jamie Rothwell and his team who are highly focussed and as a result, able to develop new products very efficiently. Despite the disruption of the pandemic, Hotbox developed and launched three new products between 2020 and 2022, as well as a whole raft of new branding and marketing material at a time when the uncertainty of the lockdown had effectively halted development of most things except PPE and vaccines.

Shuttle designed by Broome Jenkins for Hotbox

You have a reputation for designing systems furniture, designing for Hotbox is a departure, so how did your relationship with them start?

Yes, much of our past work has been furniture systems for the workplace. Therefore, what is particularly rewarding is that our initial connection with Hotbox was our workplace knowledge, and our observations about the shift to a more nomadic work style and how it was changing user needs. Our focus has always been the user, although generally within the context of the physical working environment. Hotbox’ focus is entirely the user and their ability to work anywhere. So for us this was an interesting progression and application of knowledge. In physical design terms we had to learn new things, adapt how we work and engage with a new supply chain. We had a highly experienced associate with specialist industry knowledge relevant to the first project (Shuttle) we did with Hotbox in 2019/2020. Since then we have gone on to develop several other products. Working with Hotbox highlights other privileges of being an external designer – the opportunity to keep learning and to work in a range of materials.

In the past year and a half we have seen Broome Jenkins move from solely being designers to being manufacturers with your Venue Table range. Can you explain why you made this shift and what you hope to achieve?

As a firm believer in partnerships and recognising ones’ limitations, in 2021 we embarked on an experiment to develop a product from scratch without the involvement of a client. We wanted to draw on the range of expertise and knowledge we had acquired over many years of working with leading client teams. Our main motive was efficiency across all aspects of the development project and not just the final product. This also included branding and communications. We wanted to see if we could produce a good innovative product with limited resources outside of an established corporate process. Essentially the project was about creating a clearly defined proposition to create opportunities and secure a partner with the complimentary expertise and the ability to take the product to market.

![]()

Venue Tables branding designed by Broome Jenkins

How does this differ from other speculative design?

It is especially a common practice in the furniture sector for manufacturers to receive speculative designs from hopeful designers. The manufacturer is then expected to invest in the idea which may not be fully formed or resolved. With Venue, it was our view that to be efficient with the development process and to define the opportunity for the potential partner we needed to provide an explicit product proposal with all the key questions answered. We wanted to avoid the mission creep mentioned earlier and reduce risk for the partner by circumventing the development stage, thereby saving them time and cost and to be presented with a fully rounded product.

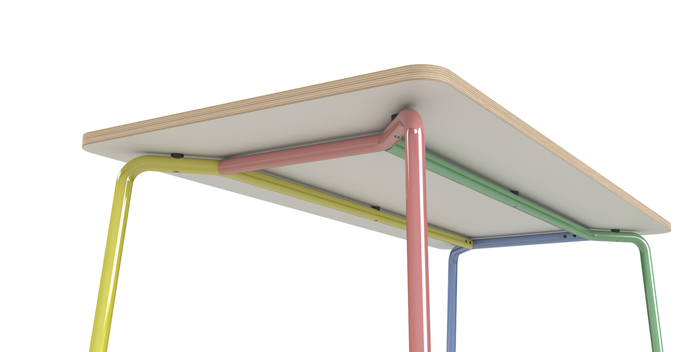

Venue Tables designed by BroomeJenkins

So having completed all the development work, engineering, patenting etc. why not continue on your own?

Although we diced with the idea of going it alone, our aim was always to find a partner who valued Venue’s inherent qualities of efficiency, adaptability and simplicity. However, we knew all along that it would be more effective and efficient to partner with someone who had the skills in logistics along with an established reputation and that all-important route to market. With the shadow cast by the pandemic, it took time and two public outings at CDW 2022 and the Workspace Design Show 2023.

However, we have recently announced a partnership with TCW a Sydney based company and leading supplier of international products into the corporate office sector throughout Australia. We are also delighted to be working with the New Design Group for the market here in the UK as well as The Irish Republic.

Venue Tables designed by BroomeJenkins

So what were you looking for in finding a partner?

As with other industries, the contract furniture sector has had its fair share of acquisitions, consolidating the market into fewer large groups and conglomerates. On a personal note I am not sure if this model will deliver agile, efficient innovation needed today. Considering that we – Broome Jenkins in size are typical of the design sector, after some exploration and a few false starts, we were drawn to companies of an appropriate scale who were doing interesting things.

With a good design heritage and a stable of Designers including Simon Pengelly and Bruce High, we felt a connection with the New Design Group and I am pleased to say they connected with Venue.

Venue Tables designed by BroomeJenkins

Although we presented Venue to them, designed, engineered, developed, tested and patent applied for, their input has been essential to refine the range into a commercially attractive product.

Similarly with TCW, they connected with the simple, adaptable and efficient design and understood the benefits of Venue’s unique frame design and universal appeal. In addition, both NDG and TCW are committed to sustainability and so the aim with Venue is that it will be made locally to the market. This means that we export ideas and methods, rather than physical products.

Venue Tables designed by BroomeJenkins

So what next for you and Broome Jenkins?

I have been in the industry one way or the other for forty years and have no plans to stop. Due in part to the pandemic, we have changed how we work and rely on various associates subject to project needs. This is a very efficient way of running a business and provides a range of skills and knowledge. We remain committed to managing good relationships with key clients and seek out people who share our values. We hope to keep working with our existing clients and will continue to develop Venue.

On a personal note, part of my time today is spent at Bournemouth University and Arts University Bournemouth (two different institutions) as a visiting tutor on several BA and MA courses. I have also recently co-written a paper with Dr Tim Reynolds that was delivered in Barcelona at the Design and Design Engineering Conference on 7 and 8 September 2023. The paper describes the learning outcomes of a project Dr Reynolds and I developed in 2020 to introduce the roles and responsibilities of product designers in a circular economy.

For me, being industrially, commercially and environmentally responsible is essential for anyone involved in the design and manufacture of products. Designers are part of the problem and have to be part of the solution.